PSR Control

Systems

We offer a variety of temperature control systems

for the operation of forehearths and distributors.

We offer a variety of temperature control systems

for the operation of forehearths and distributors.

As the prime function of the forehearth is precise glass temperature control and the main interface between the customer and the forehearth is through the temperature control system, this is an extremely important part of the overall forehearth system supply. PSR offer a variety of levels of temperature control system, for operation of individual forehearths or larger installations with several forehearths and distributors.

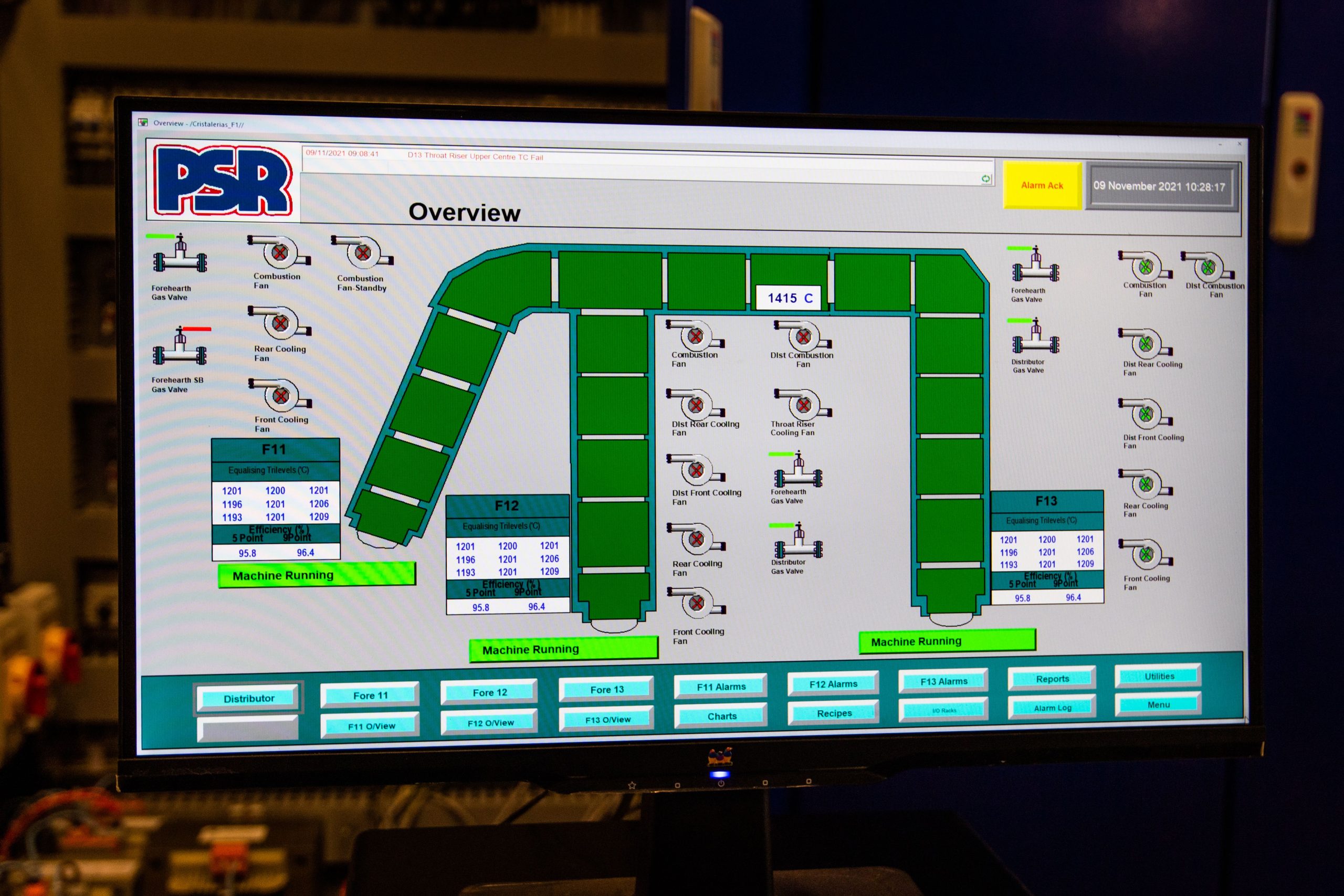

The 3000 control system is a PLC based system that combines a multi functional HMI (Human Machine Interface) with a high performance PAC (Programmable Automation Controller) to provide accurate temperature control with redundancy of processors, power supply and network.

In its 3000S form a supervisory computer is added to provide full SCADA functionality (Supervisory Control and Data Acquisition) via desktop mounted PC. Both systems can be configured for access over the internet or LAN, depending on the type and number of licences provided.

Each system supplied is bespoke and configured by PSR in cooperation with the client to ensure the correct screen format, data presentation and report generation style. The on-screen display can be translated into the local language to allow forehearth operators to make full use of system features.

If a preference is not specified by the customer we typically use Eurotherm Controls hardware which we have used successfully since the introduction of our System 5oo forehearth. However we can supply equivalent temperature control systems using hardware from other suppliers such as Siemens and Allen Bradley. The primary control strategy is negative feedback control. Using fibroptic pyrometers or thermocouples to transmit zone temperature data to the system, PID algorithms automatically modulate the cooling and combustion outputs to achieve the desired temperature.

The cascade control strategies use the equalising section central tri-level thermocouple readings to automatically adjust the forehearth temperature settings in order to eradicate vertical temperature deviations at the spout entrance. If the optional side-to-side combustion control feature is installed in the forehearth cooling zones, the trim control strategies simultaneously monitor the left-hand, right-hand and central thermocouple readings to adjust side-to-side firing levels in the cooling zones to eliminate horizontal temperature deviations at the spout entrance.

With the full PSR control strategy implemented, the operator needs only to input the desired equalising section set point and the system automatically provides the optimal spout entrance glass temperature homogeneity.

If the full System 3000S temperature control system is installed, we are able to access the system remotely from PSR with the client’s authorisation. This allows us to provide remote trouble shooting and support in addition to the on site after sales services we can provide.